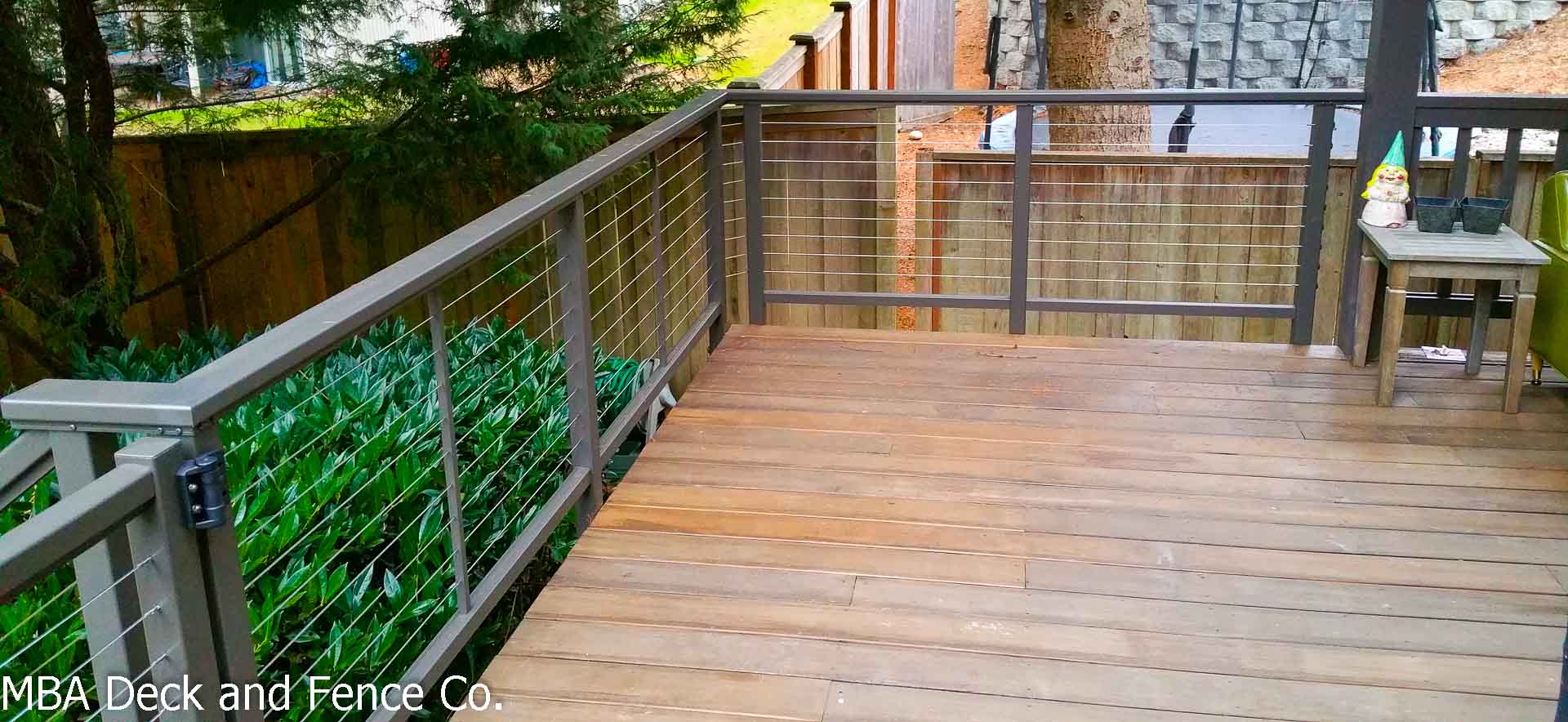

Sammamish stainless steel cable railing with gate

New railing transforms a older cedar deck

MBA Deck and Fence was tasked with updating this home’s exterior during a major remodel. The existing deck was a nice but, older clear cedar, certainly worth saving. The owner chose “bronze” from our stock color palette. Bronze blended nicely with the surrounding fir trees and complemented the darker earth tones of the home. Stainless steel cables were chosen for a modern look and our generic cable offering was chosen to keep costs down. You can see our flagship cable product here . A gate was added with self closing hinges and a keyed entry lock.

Single ended cables

One thing that is special about our “generic” cable system is that they are available with a “toggle” end. This toggle is inserted into a small diameter hole in the post and will not retract out again. This does set even our low end cable system apart from other brands which have the nut/acorn nut assembly on both ends. Using this feature allowed us to dramatically reduce the amount of visible hardware around the stairs and gate. With a conventional system the amount of visible nuts and and crimped ends would have been a visual challenge and detracted from the minimalist look.

A “non-system” allows a cleaner look and flexibility

Our railing system is dramatically different than anything in you will see in a lumber yard or big box store. It is not a system, it is more a selection of lumber like components that can be freely combined to problem solve installations. Our competitors railing systems have a prescriptive design, they have corner posts, line posts, stairposts etc… This is sometimes convenient but, restrictive when adapting to particular installations. This system approach also leads to unsightly fittings, mounting flanges and pivots that detract from the appearance. No one wants their railing to look like a plumbing project… On this product we were able to leverage this attribute to adapt to several challenges present on this existing deck. If we did a ground up we would design around the final form but, we had to work with what was there on this one. We used fascia mounts on the lower deck and stairs so that stain could be applied over the years to the cedar decking with out masking or sanding around base plates. On the balconies an odd roof rake near the deck prevented this so a surface mount was used. In extreme situations we can weld custom pieces to achieve almost any end but, in this case the owner decided to keep it simple and avoid additional fabrication cost.

There is an aspect of cable railing and most railing products that is quite troubling. There are very few railing systems or brands on the market that will actually hold and withstand a code legal tension on the cables. If you have spent any appreciable amount of time admiring cable installations you will have noticed slack or sagging cables. There are products being marketed right now by companies that advertise as “cable railing specialists” that will literally pull apart when trying to achieve correct tension. We always use a gauge that measures cable tension in foot pounds. I have personally pulled the top rail right off a system that was provided by a home builder. I have also seen end posts bend like a bow and arrow from the pressure. In most applications an end post must withstand an aggregate 1100 foot pounds of pressure to achieve adequate cable tension. Inspectors routinely state that our cables are the tightest they have ever seen. Our posts are based on a heavy duty 2 3/8″ square thick walled aluminum post with built in internal bracing specifically designed for cable applications. There is no product at Home Depot, Lowe’s or even lumber yards that have this feature. In fact you can literally crush most of these products trying to place this load on them. Feel free to send any questions you may have to me through our contact form or call and I will be happy to answer them.